Since electroformed stencils offer better paste release, Doyan has the technical ability to manufacture electroformed stencils in 2006. Electroformed stencils are suitable for fine pitch (20 mil to 12 mil pitch) SMT applications on printed circuit boards. They are also used for µBGA’s, Flip Chip, and Wafer Bumping (12 mil to 6 mil pitch).

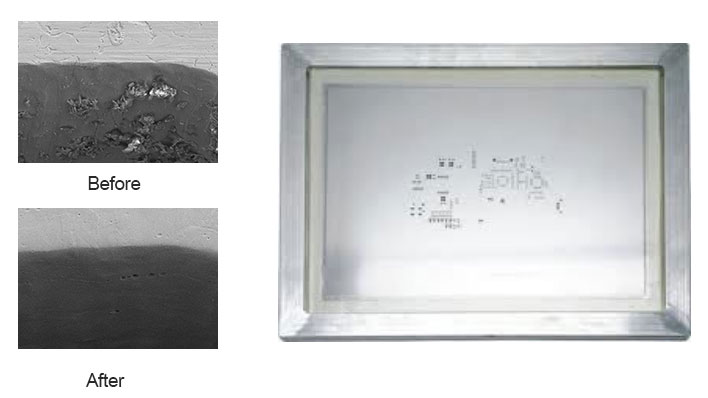

• The smooth trapezoidal sidewalls of an electroformed stencil allow for better paste release

• Nickel has a lower coefficient of friction compared to stainless steel

• Electroform foils are harder than full hard stainless steel of comparable thickness, providing for longer stencil life

Overview

Electroforming (or electro-polishing) is an additive manufacturing process which is perfectly suitable for high precision surface of framed stencil. It improves paste release and is frequently used for fine pitch (20 mil to 12 mil pitch) SMT applications on printed circuit boards. They are also used for µBGA's, Flip Chip, and Wafer Bumping (12 mil to 6 mil pitch).

Advantages:

• Smooth trapezoidal sidewalls.

• Reduced cleaning cycles.

• Higher paste transfer efficiency

Specs:

| Technology | Electroforming |

| Material | Nickel |

| Suitable Applications | All Component Pitched |

| Aperture Tolerances | ±0.0003" |

| Thickness Available | 0.001" to 0.006" |

| Positional Accuracy | ±0.0003" |

| Allow for Fiducial Data | Yes |

Electroform Stencil Limits:

| Thickness (mil) | max foil size | thickness tolerance | min aperture | min gap b/w openings |

| 0.5 to 1.0 | 12"×12" | +/-0.0001" | 0.002" | 0.003" |

| 1.0 to 2.0 | 18"×18" | +/-0.0002" | 0.003" | 0.004" |

| 2.0 to 3.0 | 21.5"×21.5" | +/-0.0003" | 0.004" | 0.004" |

| 3.0 to 4.0 | 21.5"x24" | +/-0.0004" | 0.0045" | 0.005" |

| 4.0 to 5.0 | 21.5"x24" | +/-0.0004" | 0.005" | 0.006" |

| 5.0 to 6.0 | 21.5"×24" | +/-0.0005" | 0.006" | 0.006" |

| 6.0 to 7.0 | 21.5"×24" | +/-0.0005" | 0.0075" | 0.0075" |

| 7.0 to 8.0 | 21.5"×24" | +/-0.0005" | 0.0075" | 0.0075" |